Jonathan Goenadibrata

I’m Jonathan, a robotics engineer and problem-solver who loves creating practical solutions that make everyday life easier. I get excited about building robots from scratch, designing automation that saves time, and finding ways to make technology more approachable for everyone. Curiosity keeps me learning, efficiency keeps me focused, and I’m always down to learn more, especially from the people I meet along the way.

Timeline

Meet My Robots

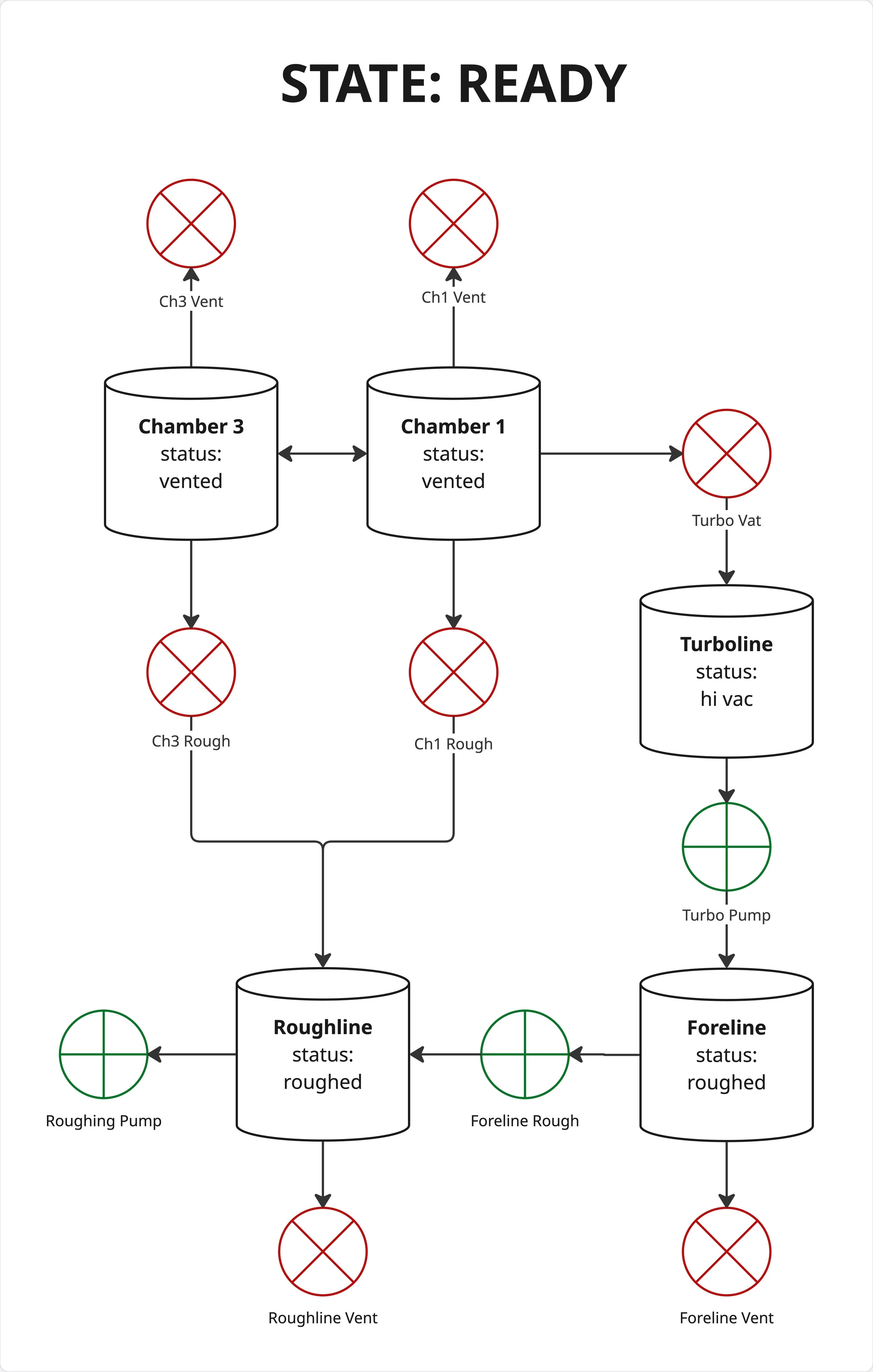

Vacuum System Automation

lykos controls - plc software

This project focuses on designing a modular CODESYS Structured Text state machine for coordinating a multi-stage vacuum system. I developed a clear, maintainable sequence for pump, valve, and chamber operations while introducing a scalable OOP architecture that replaced a legacy PAC Control workflow. This migration greatly simplified configuration, improved system clarity, and made future expansion far easier.

To support development without relying on hardware, I also implemented a node–edge pressure simulation that models chamber behavior and verifies state transitions. Together, these efforts created a more robust, testable, and extensible foundation for vacuum process automation.

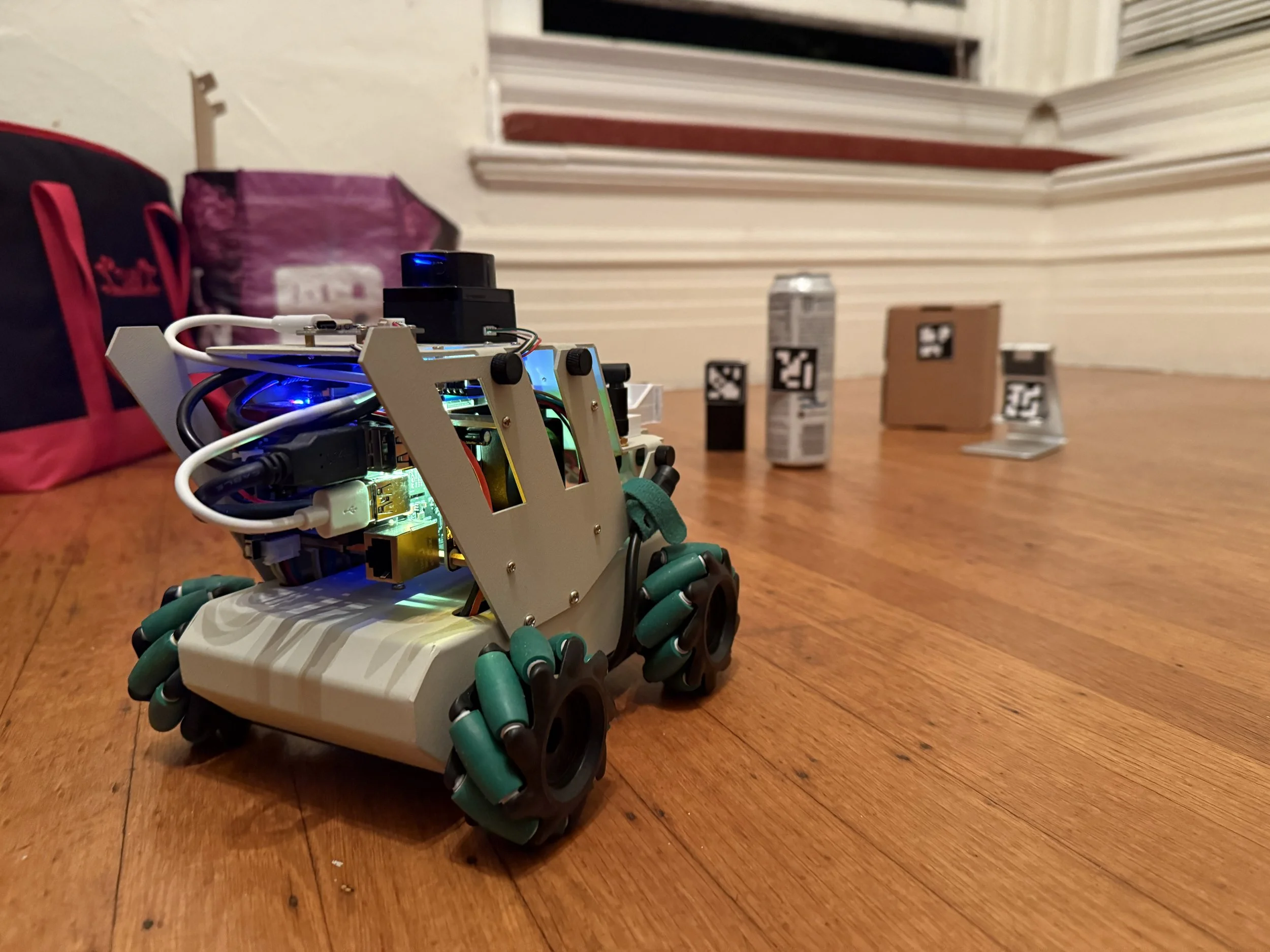

Search & Rescue Robot

uc berkeley masters of engineering capstone project

Combining perception, exploration, and navigation, my team from the UC Berkeley Master of Engineering program developed an automated exploration project as a proof of concept for search and rescue operations in natural disasters utilizing the Yahboom RDK X3 Robot.

As the engineering project manager, I oversaw project planning, delegated tasks, and ensured milestones were met on schedule, while also establishing a robust code sharing and version control workflow using GitHub.

On the technical side, I led the system design, leveraging ROS2 as the communication infrastructure between sensors, programs, and actuators. By integrating Nav2, SLAM, and OpenCV, our robot was able to autonomously navigate unknown terrain, generate maps of the environment, detect markers, and deliver first-response support.

Foreign Object Detection

apple inc. - product safety automation

At Apple Inc., I developed a Robotic Process Automation (RPA) system to automate Foreign Object Detection (FOD) testing for wireless charging devices, ensuring compliance with IEC 62368-1:2018 certification standards. Our goal was to replace long manual test cycles with a faster, more reliable process.

I programmed a Hyulim DTR-M robot in Python to place receivers (Rx) on transmitters (Tx) with metallic objects in between, while capturing real-time temperature data from devices and thermocouples. The RPA collected, processed, and visualized data in Tableau, enabling engineers to quickly interpret results. This automation reduced testing time by over 90%, cutting the process from nearly two months to one week.

In addition, I designed custom fixtures in Siemens NX to streamline device alignment and setup, reducing setup time by ~97% (1.5 hours to 2 minutes) while improving consistency and repeatability across tests.

TriFinger Robotics

uc san diego bachelor of science capstone project

Our team of four designed and built the TriFinger, a three-finger robotic manipulator inspired by the Open Dynamic Robot Initiative. The goal was to create a low-cost, accessible platform for grasping and manipulation tasks that could be easily manufactured and reproduced for research and education.

I served as the software lead, developing an in-house inverse kinematics solver and motor control algorithms in Arduino C on the Arduino Mega 2560. The system achieved a resolution of 0.2° per step, enabling precise 9-DoF movements. I also created a GUI for serial communication, allowing users to issue commands and monitor the robot in real time.

To reduce costs, our team designed every component in-house and fabricated parts with SolidWorks CAD and 3D printing. These design choices lowered the build cost from $5,000 to $1,800—a 64% reduction—while still delivering a precise, reliable, and fully functional robotic platform for students and researchers.

Contact Me!

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!