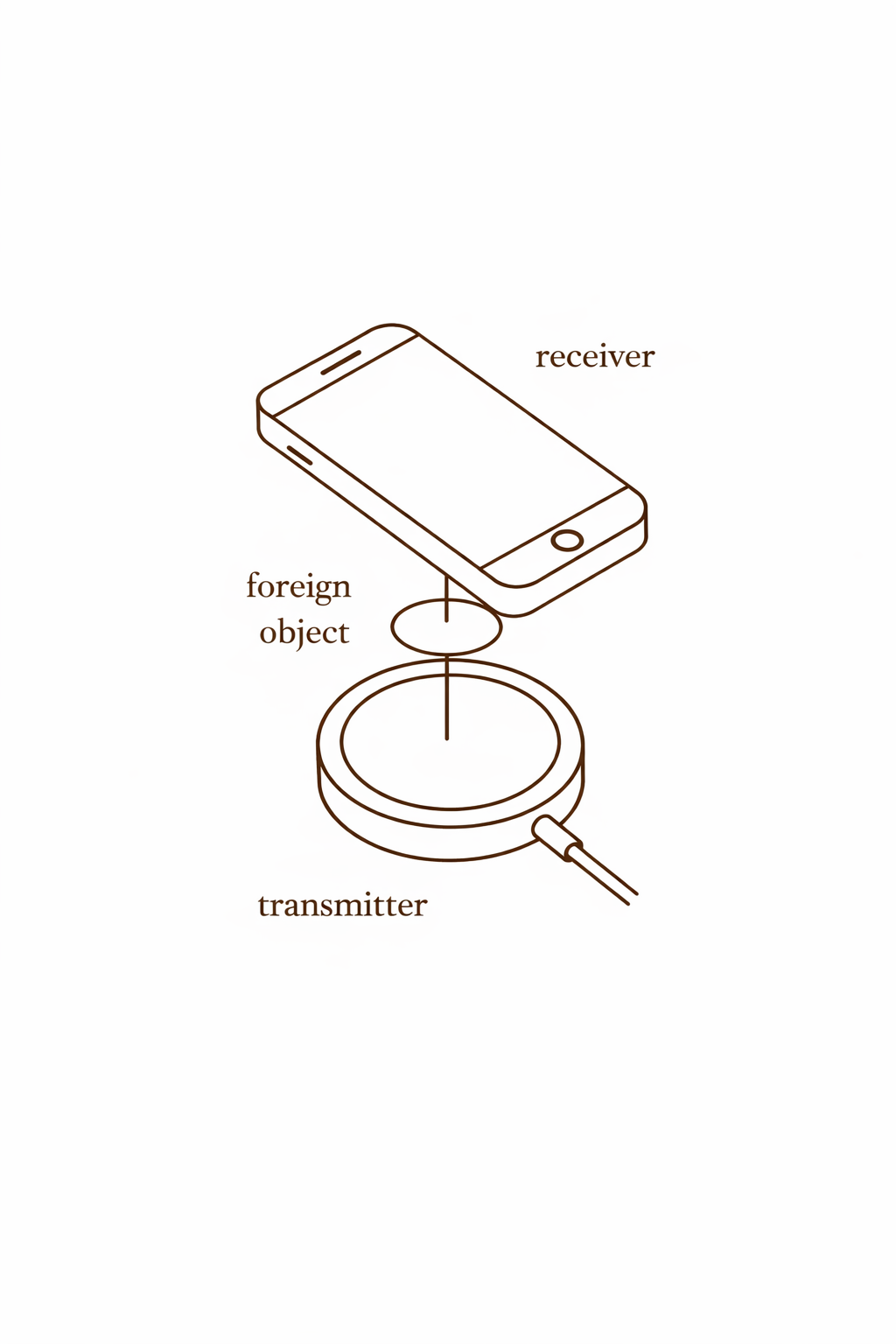

Foreign Object Detection

Apple Inc. : Product Safety Automation

Product Safety Engineers spends around 4–6 hours per day running simple tests that, while individually low in complexity, were required at high volume for certification.

“Low Complexity”

FOD testing in 3 simple steps

01.

Place Foreign Object

02.

Turn On Wireless Charger

03.

Collect Temperature Data

“High Volume”

how many testings we need to do per product every year?

3

Foreign Object Types

3

x

Foreign Object Location

2

x

State of Charges

2

x

Test Sequences

3

x

Spacer Heights

25

x

Rx-Tx Alignment

↓

2700

Total Tests per Product

How to better allocate time for engineers in order to maximize human problem-solving where it matters most?

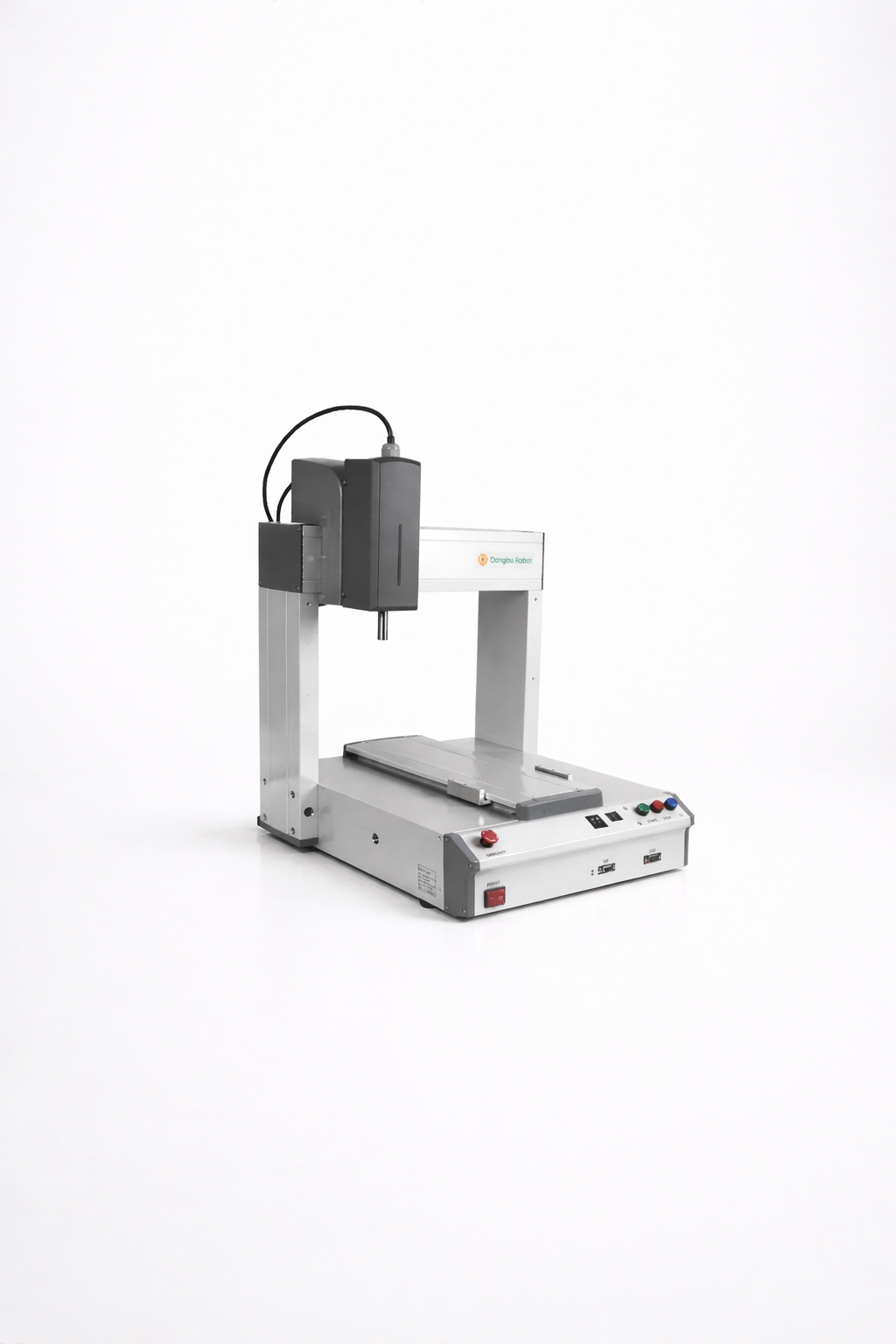

Automation System

-

We built a robotic testing system that autonomously executes simple tests with minimal setup, removing the need for manual test execution by engineers.

-

The system manages all device preparation, including charging, draining, and configuring devices for each test scenario, ensuring consistent and repeatable test conditions.

-

Once running, the system executes tests continuously and unattended, including overnight. Its modular design allows horizontal scaling to run multiple systems in parallel and meet high-volume testing requirements.

By designing the system for horizontal scaling, we reduced test time from three months to two weeks per product under normal capacity, while maintaining the same turnaround time when running three products in parallel at full capacity.

Strength in Numbers

Side Projects

Device Marker Project

Magnetic Probe Spacer Project

image coming soon

Contact Sensor End Effector Project

image coming soon